Case Study: Unifying Manufacturing Data with a Data Fabric Architecture

Making Manufacturing Data Easy with Data Fabric

Let’s be honest: manufacturing data is everywhere.

On the shop floor? Check.

In your ERP? Definitely.

On cloud dashboards, you forgot you subscribed to? Also yes.

This data explosion, fed by IoT sensors, automation, and legacy systems, has created a serious challenge: How do you actually use it all?

That’s where data fabric steps in.

Think of it as the connective tissue that brings together scattered, disconnected data and turns it into something useful. Whether it’s edge-to-cloud integration or making sense of decades-old systems, a strong data architecture strategy is the foundation modern manufacturers are building on.

And it’s not just theory. Enterprises applying data fabric in manufacturing are seeing real impact:

- smarter decisions

- more accurate manufacturing analytics

- and fewer surprises on the floor.

Why 78% of Manufacturing Data Goes to Waste

Here’s a wild stat: manufacturers generate over 2 exabytes of data every year.

But less than a quarter of that data gets used.

That’s not just inefficiency. That’s lost revenue, missed quality flags, and hidden insights slipping through the cracks.

By unifying their data using data fabric architectures, industrial enterprises are finally able to:

- break down isolated systems across teams

- unlock predictive maintenance instead of waiting for downtime

- streamline operations with a bird’s-eye view

This isn’t just IT speak, it’s digital transformation in manufacturing, in action.

The Real Problem? Siloed Systems That Don’t Talk

Walk into any production facility and you’ll likely see this:

- Machines installed 15 years ago

- IoT sensors installed last quarter

- A cloud dashboard someone set up two months ago

- And a team trying to connect them all with duct tape and hope

This patchwork setup leads to isolated systems, inconsistent data, and a total lack of visibility. That’s what the industry calls data isolated systems, and they’re a major barrier to agility.

Old-school point-to-point integrations? They don’t scale. Especially when you’re growing, merging, or modernizing.

What manufacturers need instead is a unified, flexible framework, a.k.a. data fabric, that enables seamless data connectivity across every touchpoint. That’s how you go from reactive firefighting to proactive strategy.

Because at the end of the day, smart factory data means nothing if you can’t connect the dots.

The Data Fabric Architecture Solution

Manufacturing data lives everywhere. On machines. In cloud dashboards. Across spreadsheets. Inside legacy systems, no one remembers setting up.

And most teams? Still stitching it all together manually.

That’s where a data fabric strategy makes the difference. It doesn’t rip apart your existing systems. It weaves them together, virtually.

No heavy lifting. No mass migration.

Instead, it creates an intelligent, unified layer that connects disparate manufacturing data sources, making data available in real-time, from wherever it lives.

Let’s break down what that looks like:

- Distributed Data Access

Whether your data is stored in your own facility, in the cloud, or at the edge, data fabric enables seamless access without duplicating or moving it. That means fewer disruptions and preserved legacy investments. - Intelligent Data Cataloging

With built-in metadata management, your data doesn’t get lost in separate departments. Everything gets auto-discovered, classified, and made findable, ending the chaos of “dark data” no one can trace. - Real-Time Data Connectivity

Batch or streaming, this architecture handles both. That means you can react to operational shifts instantly, instead of waiting for reports that arrive a week too late. - Scalable Integration Framework

Whether you’re expanding operations or introducing new machines, your data architecture strategy stays flexible. No need to redesign from scratch every time something grows.

It’s smart. It’s adaptable. And it’s built for the complexity of digital transformation in manufacturing.

Technical Implementation Of Data Fabric

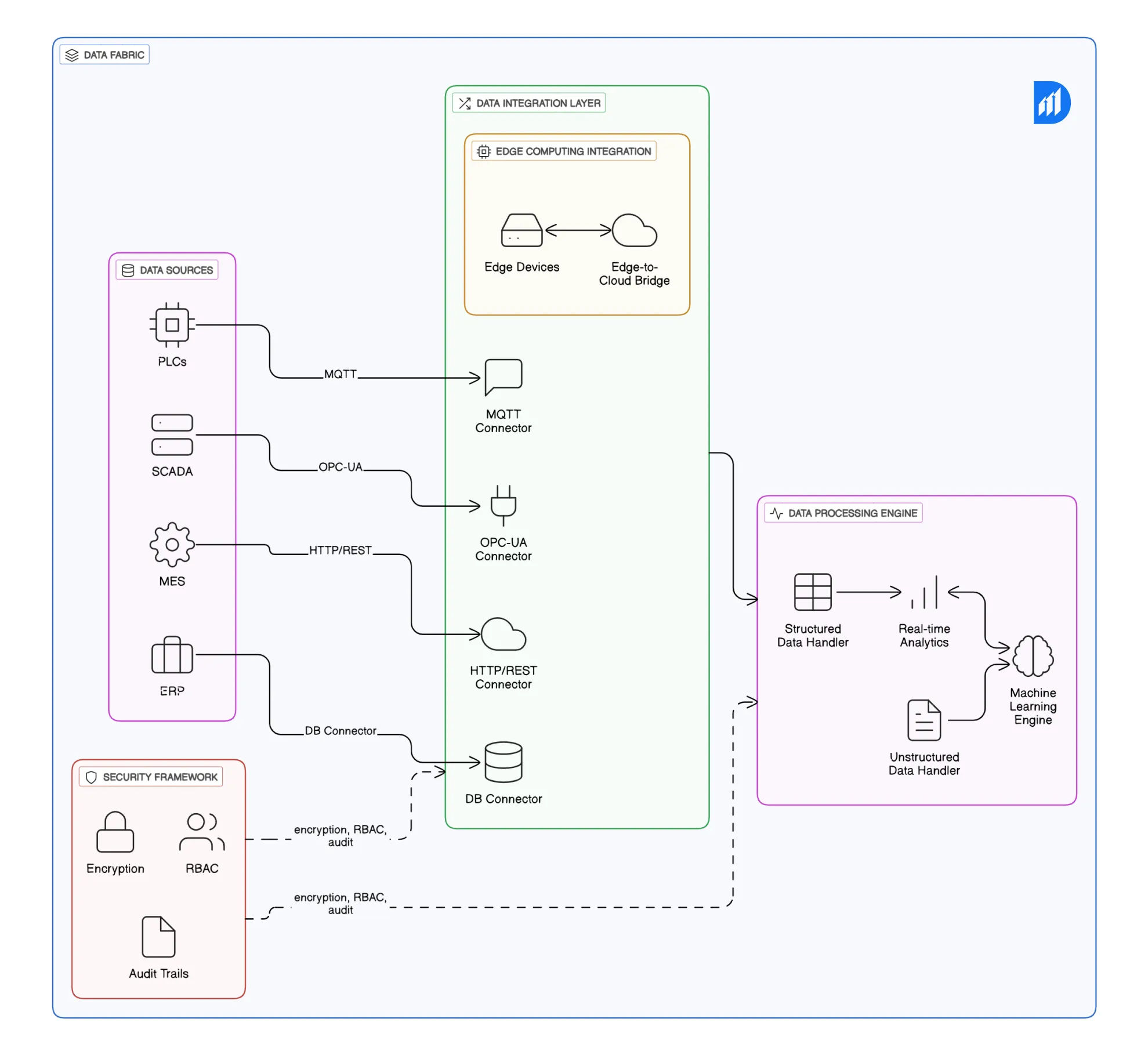

Implementing a data fabric in a manufacturing environment isn’t just about plugging in a few connectors. It’s about building a strong, secure, and flexible foundation. Here’s what that entails:

- Data Integration Layer

This is where the real thing happens. It connects with your SCADA, MES, PLCs, and ERP systems, using protocols like OPC-UA, MQTT, HTTP/REST, and traditional database connectors. This is key to achieving manufacturing data integration without data chaos. - Data Processing Engine

Think fast, real-time processing. You’ll need distributed systems that handle structured and unstructured data while supporting manufacturing analytics and machine learning. Speed matters when insights need to drive operations on the floor. - Security Framework

You’re dealing with sensitive data. From proprietary processes to critical machine settings. That’s why encryption, RBAC (role-based access controls), and audit trails aren’t optional; they’re foundational. This architecture is built to meet enterprise-grade data management standards. - Edge Computing Integration

A modern smart factory isn’t centralized; it’s distributed. Edge-to-cloud integration ensures your edge devices talk seamlessly with your centralized systems. Local decisions happen fast, while the bigger picture stays connected.

This is how you unify manufacturing data using data fabric, not by rebuilding, but by intelligently connecting. The result? Faster decisions, deeper visibility, and a backbone strong enough for any smart factory evolution.

And the best part?

It scales with you.

Whether you’re rolling out predictive maintenance, optimizing supply chains, or diving into real-world data fabric use cases in manufacturing, this architecture is built to support your journey, end to end.

Case Study: How a Data Fabric Transformed a Fragmented Automotive Giant

Imagine running 15 factories, each with its own legacy systems, sensors, and scattered separate departments. That was reality for one leading automotive manufacturer.

With 200+ systems ranging from 30-year-old machines to cloud-native platforms, they were flying blind, with no unified view, no consistent quality checks, and no way to replicate success from one plant to another.

So, what changed?

They adopted a data fabric architecture, not by ripping and replacing, but by layering a smart, connected foundation across their existing infrastructure.

Implementation Strategy: Stitching Data Without Starting Over

The goal wasn’t to disrupt. It was to connect.

By introducing a virtualized data layer, the team enabled seamless manufacturing data integration across plants, without asking operators to abandon tools they already used.

Each site had its own distributed data processing node, all tied together via secure, high-speed connections to a centralized analytics platform. Think of it as edge + cloud, but with no friction.

Add to that: real-time streaming of production metrics, quality stats, and equipment performance, feeding into one unified dashboard.

The Impact? Measurable and Massive

Within just six months:

- OEE (Overall Equipment Effectiveness) shot up by 23%

- Unplanned downtime dropped by 31%

- Predictive maintenance saved nearly $2.3M in potential failures

That’s the power of a data architecture strategy that prioritizes connectivity, agility, and insight.

Why Data Fabric Matters for Industrial Enterprises

If you think data fabric is just another IT buzzword, think again. In manufacturing, it’s a game-changer.

Here’s why:

1. Full Operational Visibility

No more “I didn’t know.”

With unified manufacturing analytics, real-time dashboards surface trends, bottlenecks, and blind spots before they become problems.

2. Smarter Predictions

Integrating real-time and historical data enables predictive analytics that actually work, anticipating machine failures, supply disruptions, and quality dips.

3. Quality Without Guesswork

With connected data points from across the line, you’re no longer fixing symptoms. You’re solving root causes, making quality management proactive, not reactive.

4. Compliance, Handled

Regulations demand traceability. With enterprise data management backed by a data fabric, automated reports and audits become the norm, not a fire drill.

Edge-to-Cloud: The Smart Factory Sweet Spot

Smart factory data isn’t just created in the cloud. A lot of it is born at the edge, on factory floors, in sensors, and on machines that can’t wait for latency.

Here’s how edge-to-cloud integration solves that:

Edge Nodes Handle the Now

Fast decisions, like shutting down a machine or flagging a quality risk, happen at the edge, where milliseconds matter.

Cloud Powers the Big Picture

The cloud platform crunches the heavy stuff: machine learning, long-term trends, strategic forecasting.

The Data Fabric Keeps It Seamless

Behind it all? The data fabric ensures data flows smoothly between edge and cloud, deciding what’s processed where, based on speed, sensitivity, and scale.

Analytics That Drive Real Decisions

When data is unified, business intelligence becomes something you use daily, not a dashboard you forget.

Real-Time KPIs

From machine uptime to shift performance, managers can spot red flags and fix issues, before they snowball.

Smarter Forecasting

With clean, connected historical data, demand forecasts, resource planning, and maintenance schedules become data-driven, not gut guesses.

Supply Chain Sync

It’s not just about what happens inside the factory. With the right data architecture strategy, manufacturers get visibility across their entire supply chain, from supplier delays to changing demand patterns.

Implementation: From Chaos to Cohesion (Yes, It’s Possible)

Implementing a data fabric architecture in manufacturing isn’t about flipping a switch; it’s about orchestrating change across people, processes, and platforms. Here’s how smart enterprises do it right:

Start Small, Scale Smart

Jumping headfirst into a complete transformation? Tempting. Risky. Instead, the most successful manufacturing data integration efforts start with focused pilot projects. Prove value. Learn fast. Then scale with confidence.

Bring People Along

Technology can’t work in isolation. For real digital transformation in manufacturing, your team needs to come along for the ride. Think training, process reboots, and culture shifts, not just shiny new tools.

Build on Governance, Not Guesswork

Unified data = big power. But also big responsibility. Without a solid enterprise data management framework, covering access, ownership, quality, and security, you’re inviting isolated systems to creep right back in.

Choose Partners Like You Choose Co-Founders

Implementing a data architecture strategy for complex manufacturing environments? You’ll need experts who’ve done it before. The right tech partners help you move faster and avoid pitfalls along the way.

What Future-Ready Manufacturing Actually Looks Like

Let’s get real: smart factory data isn’t about buzzwords. It’s about preparing today for what’s next, and next is coming fast. With data fabric at the core, here’s what modern manufacturing leaders are building toward:

AI That Knows What’s Next

You can’t run AI on guesswork. But with unified, real-time data flowing through your systems, advanced analytics and manufacturing analytics become supercharged. Forecast demand. Spot failures. Automate decisions.

Digital Twins with Real Impact

A strong data fabric enables accurate, dynamic digital twins. These aren’t just cool models, they’re living systems that mirror your shop floor and help simulate, test, and optimize everything.

Systems That Run Themselves (No, Really)

As automation scales, your data infrastructure needs to think ahead. That’s where edge-to-cloud integration meets autonomous ops. Machines make decisions. Lines self-optimize. You supervise smarter.

So, Why Does All This Matter?

Because real-world data fabric use cases in manufacturing are showing one thing loud and clear: unified data isn’t just a nice-to-have, it’s your edge.

When you stop treating data like exhaust and start treating it like the fuel it is?

That’s when operations sharpen.

Quality improves.

Efficiency soars.

And your entire business strategy starts breathing easier.

Whether you’re looking to modernize operations or prepare for a more autonomous, connected future, data fabric is the architecture that makes it all possible.

Your Next Step? Just Ask.

Ready to unify your manufacturing data using a data fabric?

Let’s make it happen, without the confusion, complex terms, or 10-month delays.

Book a free consultation with our data fabric specialists today.

We’ll help you map a clear, customized strategy to harness the benefits of data fabric for industrial enterprises like yours.

Let’s turn your data into decisions.

Your operations into outcomes.

And your vision into value.

.webp)

Comments

Post a Comment